The Ulimate Mixer has integrated mixing and dispersing, with the characters of mature technology, stable operation, and convenient maintenance, convenient feeding, mixing and dispersing respectively. The dual-planet mixer designed and developed by our own company can meet the new demands of mixing equipment raised by the constantly developing slurry making processes. In the R&D process, we always persisted in the aim of making the drive system more reasonably, the operation more stably, the sealing system more perfectly, the structure of mixing and dispersion more sophistically and the control system more user-friendly, we have developed this mixing equipment whose working process with no dead corner or climbing, and with better air-tightness and temperature measurement accuracy, higher revolving speed, lower noise level, and higher stability.

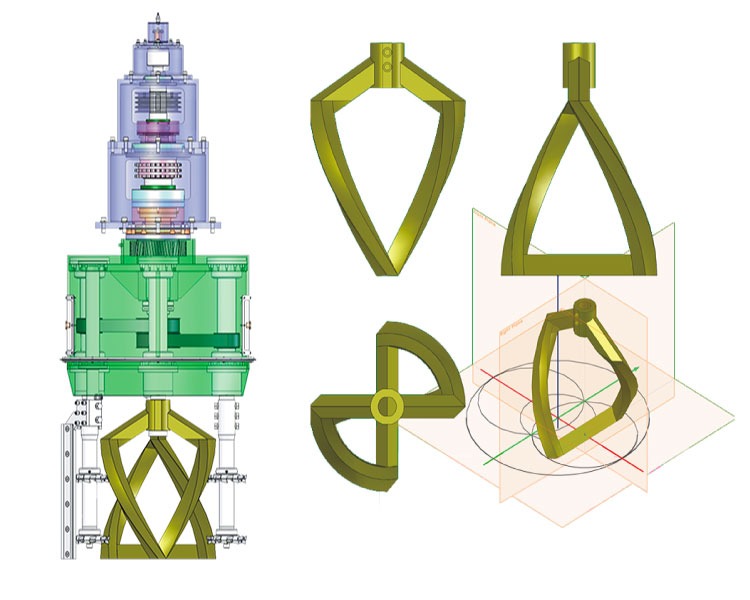

In the whole process of product development, we make use of CAD technology; thoroughly solving the phenomena of deformation, shift, and interference resulted from the heating of principal axes and bearings during the running process of mixed equipment by use of the finite element analysis technology. The more reasonable and sophisticated transmission structure makes the equipment run more stably and maintain more conveniently.

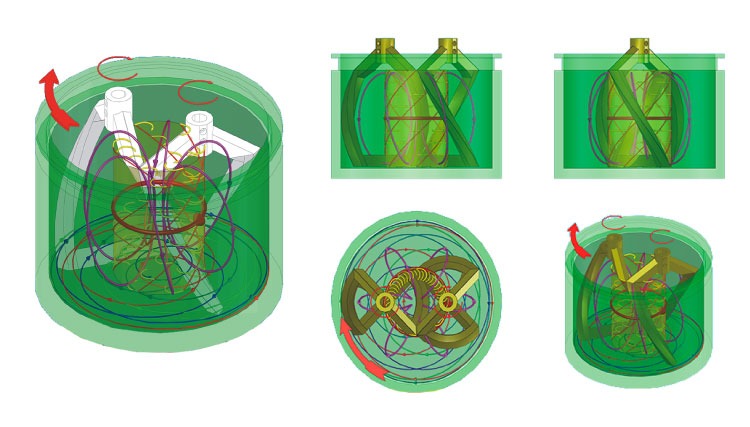

Reasonable flow field design is the key factor to determine the stirring effect of the mixing equipment. For the requirements from clients of multiple manufacturing techniques, formula, and for match the features of material viscosity and liquidity, our company has designed stirring flow field as spiral propulsion flow field, which follow the direction of revolution. This flow field enables stirring mixing and dispersive mixing to establish a steady three-dimensional turbulent flow of material under the matched revolution and rotation speed, so as to meet the demand on faster, better and more steady mixing.

In the design of mixing flow, we use the analytical method of accurate computer-assisted three-dimensional simulation of flow field. Starting from the principle of agitation and dispersion and through the actual simulation and prototype test, we have found out the most reasonable agitation and dispersion form and their matching mode.

The stirring paddle adopts the double helix form similar to DNA. The two sets of the stirring paddle are placed on the same turntable with a 90-degree angle between them; they do the orbital movement around the axis when rotating. The two paddles establish the kneading point in the running process automatically.

improve its uniformity, but also shorten the dispersion time greatly