Function of Emulsion pump

- Emulsification

- Shearing

- Mixing

- Dispersion

- Crushing

- Transportation

Application of Emulsion pump

- Narrow space

- medium and large batch online continuous production or cyclic processing production process

- Food industry: milk, beer, chocolate, syrup etc.

- Daily use chemicals: cosmetics, fragrance, toothpaste, detergent, shampoo, shoe polish, soap, face cream etc.

- Pharmaceutical industry: emulsifier, syrup, nutrition, medicine, Paste the pharmaceutical, bio-products etc.

- Chemical industry: paints, dyes, paints, oil agent, emulsified asphalt, adhesives, leather goods etc.

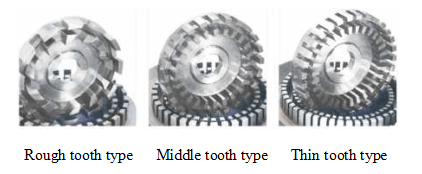

Rotor Type

Product Parameter and shape size of Emulsion pump

|

Model |

Power(KW) | Rotation speed(r/min) | Handing capacity(L) | D | D1 | H1 | D2 | D3 | H |

|

TRH80 |

1.5 | 2900 | 20-100 | 105 | 105 | 500-750 | 200 | 105 | 705 |

| TRH100 | 2.2 | 2900 | 50-300 | 116 | 160 | 550-850 | 215 | 260 |

1150 |

|

TRH120 |

4 | 2900 | 100-500 | 141 | 195 | 750-900 | 255 | 260 | 1300 |

| TRH140 | 5.5 | 2900 | 200-800 | 156 | 235 | 800-1000 | 280 | 330 |

1520 |

|

7.5 |

2900 |

||||||||

|

TRH160 |

11 | 2900 | 300-1000 | 184 | 235 | 900-1200 | 280 | 330 | 1655 |

|

15 |

1450 |

||||||||

|

TRH180 |

18.5 | 1450 | 500-1500 | 200 | 280 | 1000-1400 | 360 | 415 | 2070 |

| TRH200 | 22 | 1450 | 800-2000 | 240 | 300 | 1100-1600 | 360 | 415 |

2130 |

|

TRH220 |

30 | 1450 | 1000-3000 | 260 | 320 | 1200-1800 | 400 | 450 | 2525 |

| TRH240 | 37 | 1450 | 1500-5000 | 280 | 340 | 1300-2000 | 400 | 450 |

2585 |

|

TRH270 |

55 | 1450 | 2000-8000 | 330 | 380 | 1400-2200 | 500 | 550 | 2995 |

| TRH290 | 75 | 1450 | 3000-10000 | 350 | 400 | 1500-2400 | 500 | 550 |

3050 |