In the high viscosity of emulsion, especially the manufacturing process of cream, ointment, emulsion products:

The problem you are facing:

- One is: The dispersed phase particle size and mixing the air mixed with products, grain size is too large a everywhere emulsion instability, lack luster

- The other is: Products into the air will make the products bubble, bacterial contamination, easy oxidation and the appearance is not smooth.

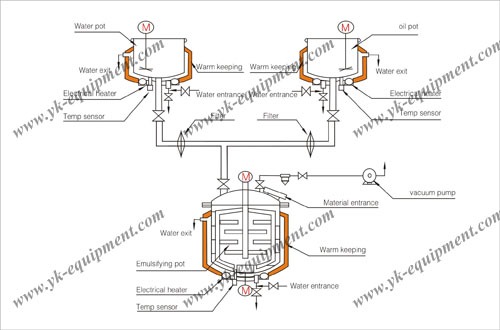

The solution——ZJR series vacuum homogeneous

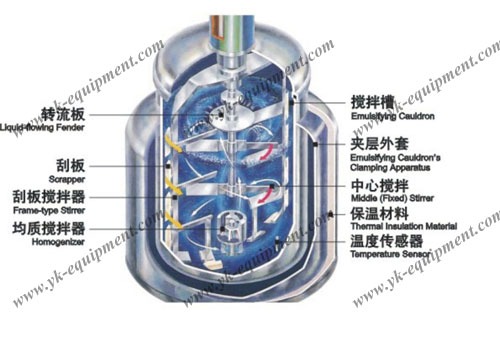

- By mixing with high-quality mixing blades, scraping the walls, and stirring in the center, they complement each other to form the best mixing method and achieve a perfect mixing product.

- The color and vacuum pumping method ensure that there are no bubbles during the mixing process at the production outlet, which can produce high-quality products with luster, delicacy, and good ductility.

Advantages of Emulsifying Mixer

1. Better emulsification result

- Lotion is more stable, and the droplet size is less than 5um

2. Suitable for high viscosity materials

- up to 80000mpas in viscosity

3. High precision

- PID temperature control, rapid heating

4. Safety

- There is an insulation layer outside the heating inter-layer to prevent operators from getting burned

5. Convenience

- The structure is easy to clean and maintain

6. Support customized functions

- vacuum/sterile/explosion-proof/voltage

Product parameters

| Name | Z J R-250 | Z J R-350 | |

| Emulsifying Pot | Design Volume (L) | 250 | 350 |

| Capacity (L) | 200 | 280 | |

| Scraper Stirring Power (KW) | 2.2 | 2.2 | |

| Scraper Stirring Speed (rpm) | 0-65 | 0-65 | |

| Homogenizer Power (KW) | 4 | 4 | |

| Electrical Heating Power (KW) | 12 | 12 | |

| Homogenizer Speed (rpm) | 2800 | 2800 | |

| Water Pot | Design Volume (L) | 160 | 250 |

| Capacity (L) | 128 | 200 | |

| Power (KW) | 0.75 | 0.75 | |

| Speed (rpm) | 1400 | 1400 | |

| Electrical Heating Power (KW) | 8 | 12 | |

| Oil Pot | Design Volume (L) | 130 | 250 |

| Capacity (L) | 105 | 150 | |

| Power (KW) | 0.75 | 0.75 | |

| Speed (rpm) | 1400 | 1400 | |

| Electrical Heating Power (KW) | 8 | 12 |

| Name | Z J R-2 5 0 L | Z J R-3 5 0 L | ||||

| Length | Width | Height | Length | Width | Height | |

| Emulsifying Pot Rack | 1850 | 1105 | 2480-3480 | 2000 | 1350 | 2750-3850 |

| Water and Oil Pot Rack | 1800 | 768 | 1600 | 2000 | 868 | 1650 |

| Table | 1800 | 700 | 2000 | 750 | ||

| Overall | 2570 | 1900 | 2480-3480 | 2950 | 2720 | 2750-3850 |

| Name | ZJR-650 | ZJR-850 | |

| Emulsifying Pot | Design Volume (L) | 650 | 850 |

| Capacity (L) | 520 | 680 | |

| Scraper Stirring Power (KW) | 4 | 4 | |

| Scraper Stirring Speed (rpm) | 0-65 | 0-65 | |

| Homogenizer Power (KW) | 11 | 15 | |

| Electrical Heating Power (KW) | 18 | 18 | |

| Homogenizer Speed (rpm) | 2800 | 2800 | |

| Water Pot | Design Volume (L) | 400 | 500 |

| Capacity (L) | 320 | 400 | |

| Power (KW) | 1.1 | 1.1 | |

| Speed (rpm) | 960 | 960 | |

| Electrical Heating Power (KW) | 18 | 18 | |

| Oil Pot | Design Volume (L) | 320 | 400 |

| Capacity (L) | 250 | 300 | |

| Power (KW) | 1.1 | 1.5 | |

| Speed (rpm) | 960 | 960 | |

| Electrical Heating Power (KW) | 12 | 12 |

| Name | ZJR-650L | ZJR-850L | ||||

| Length | Width | Height | Length | Width | Height | |

| Emulsifying Pot Rack | 2500 | 1350 | 3230-4560 | 2650 | 1450 | 3350-4750 |

| Water and Oil Pot Rack | 2500 | 1150 | 1950 | 2650 | 1250 | 1950 |

| Table | 2500 | 850 | 2650 | 850 | ||

| Overall | 3650 | 3420 | 3230-4560 | 3750 | 3550 | 3350-4750 |

Can this be the best for reconstitution of powdered milk to liquid milk? If so what is the price?

We are looking for high shear mixing unit include hot water tank for Cmc & xanthan gum for juice manufacturing, capacity 600L per hour.