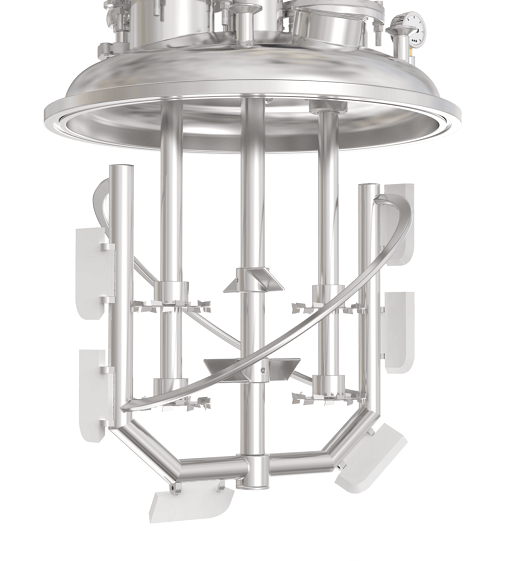

Toothpaste Making Mixing Machine

- Toothpaste making

- High viscosity materials

Advantages

- More efficient

- Lower loss

- Lower pollution

- More stable performance

- Easier operation

- Automation

Product description of Toothpaste Making Mixing Machine

- Equipped with a high-speed disperser or high shear homogenizer, the powder and liquid materials are mixed through high-speed rotation and rotated in the pulping pot to make the materials uniform and delicate.

- Equipped with paddle type stirring scraper to prevent material accumulation and dead corners.

- The movable scraper can automatically adhere to the inner wall, scrape materials, and ensure uniform temperature.

- The paste is made in a sealedtank and operated under vacuum.

- Equipped with a bipolar vacuum pump, the final vacuum inside the tank can reach -0.098MPa.

- The water tank is made of high-quality stainless steel with a jacket for heating or cooling.

Product parameters of Toothpaste Making Mixing Machine

|

Model |

Design volume(L) | Max. useful volume (L) | Min. Usefulvolume(L) |

Dimensions (Lx Wx H mm) |

|

ZGJ-15 |

15 | 12 | 5 |

2600x1900x2500(3500) |

|

ZGJ-50 |

50 | 40 | 15 |

3000x2750x2750(3850) |

|

ZGJ-100 |

100 | 80 | 30 |

3650 x 3400 x 3300(4560) |

|

ZGJ-350 |

350 | 280 | 100 |

3750x3550x3350(4800) |

|

ZGJ-650 |

650 | 500 | 200 |

4900x3300x3000(4600) |

|

ZGJ-1300 |

1300 | 1000 | 400 |

4800x4400x3300(4800) |

Please send your needs to

sales@yk-machine.cn

Metallic Tube Filling & Sealing Machine is mainly used to fill the material into metal tubes with fixed quantity and then seal the tube. It is often used for filling and sealing in toothpaste packaging.