Application of Double Planetary Mixer

High viscosity substances such as

-

paste cosmetics

- additives

- Lubricants

- paste materials

- encapsulating adhesive ointments

- adhesives

- pigments

- sealants

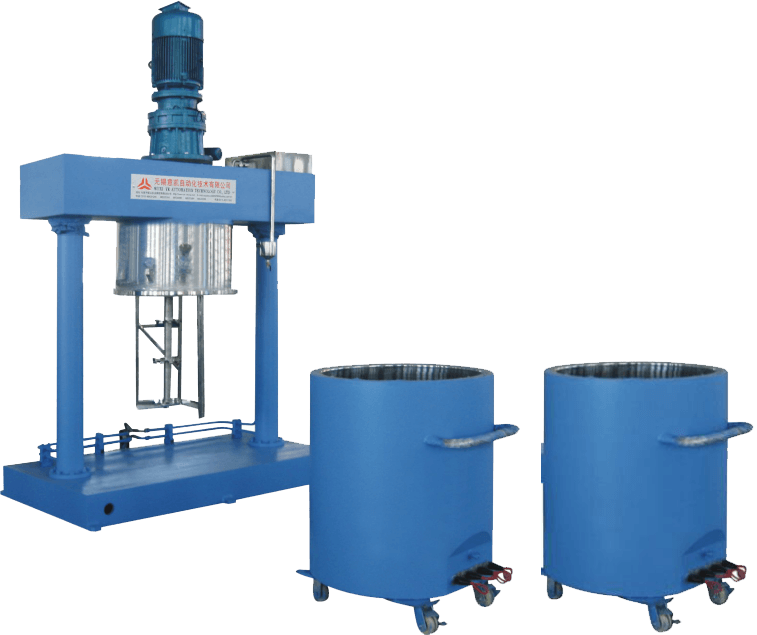

Product description Double Planetary Mixer

1. More Efficient

The host adopts planetary gear design, low noise, high mechanical efficiency, which can save power usage and reduce equipment space occupation

2. Wider applicability

This equipment is suitable for the mixing, reaction, dispersion, dissolution, and tempering of multi-component solid-solid, solid-liquid, and liquid-liquid materials

3. Higher viscosity

The viscosity range of the equipment is around 10000-20000000 MPas

4. Lower speed and higher torque

High viscosity and thixotropic materials can be thoroughly mixed and dispersed without overheating.

5. Various mix forms

Multiple blade, frame, butterfly, outer wheel, etc. can be installed according to material requirements.

6. Optional explosion-proof or anti-corrosion configurations.

Product parameters

|

Model |

Design volume(L) | Max useful volume(L) | Min useful volume(L) |

Dimensions(L*W*H/mm) |

|

SXJ-10 |

10 | 8 | 1.5 | 990*910*2360 |

| SXJ-50 | 57 | 40 | 5.5 |

1200*760*2100(2750) |

|

SXJ-100 |

108 | 80 | 7.5 | 1550*800*2650(3350) |

| SXJ-200 | 200 | 160 | 11 |

1700*950*2760(3660) |

|

SXJ-300 |

350 | 300 | 15 | 2000*1100*3160(4100) |

| SXJ-500 | 505 | 400 | 22 |

2150*1250*3380(4400) |

|

SXJ-1000 |

1045 | 800 | 37 |

2450*1580*3860(5100) |

Supporting equipment——planetary press