Application of Recirculation Homogenizing Mixer

- Cosmetic Cream

- Medicine Ointment

- Salad dressing

- Mayonnaise

- Muspensions

- Creams

- Emulsions

- Gels

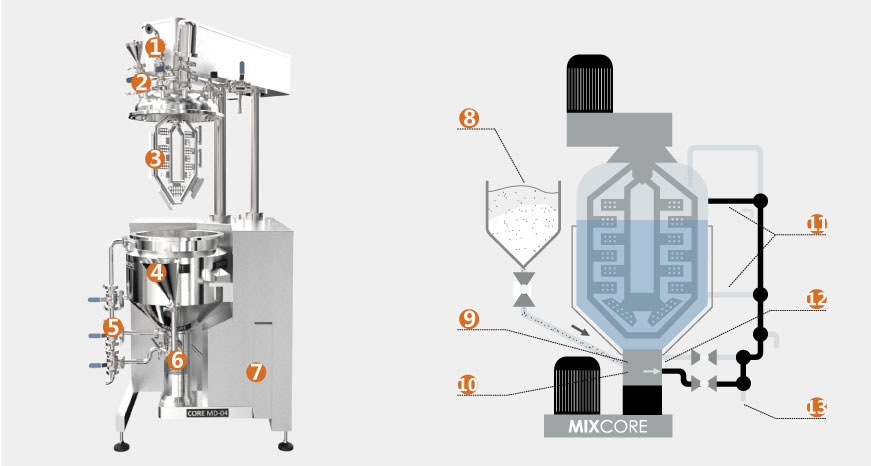

Operating Principle

Mixcore ® Recirculation Homogenizing Mixer allows for efficient mixing, dispersing, heating/cooling, and optimum feeding of additives.

The innovative mixing plant enables the processing of high viscous products, also under pressure and vacuum.

(1) All stainless steel system

(4) Feeding hopper can add powder or liquid

(7) Control cabinet can be designed as PLC or button contro

(10) Dispersing head(it composed of sophisticated stator and rotor, which achieve best dispersing effect)

(13) Discharge hole

(2) Connector can connect air compressor, feeding hopper, filter, etc

(5) Circulating tube

(8) Feeding(feed solid and liquid additives directly into the working chamber, then mix quickly and completely to avoid clumping)

(11) Outlet (the length of the circulation line depends on the production)

(3) Contrarotating agitator with scraper

(6) High speed dispersion system

(9) Rotor pump( the rotor inhale mixture, meanwhile, circulate and mix under low shear stress

(12) Throttle valve(produce negative pressure by inhaling material, no need to use vacuum in mixing tank)

Product parameters

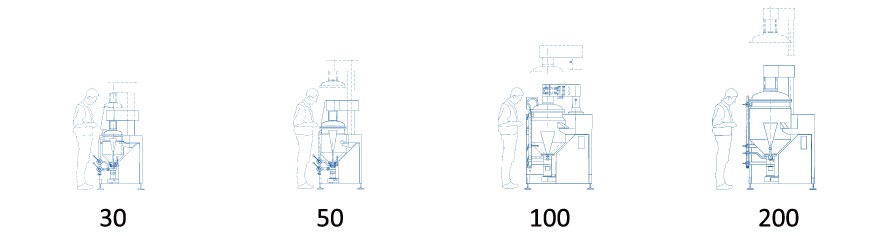

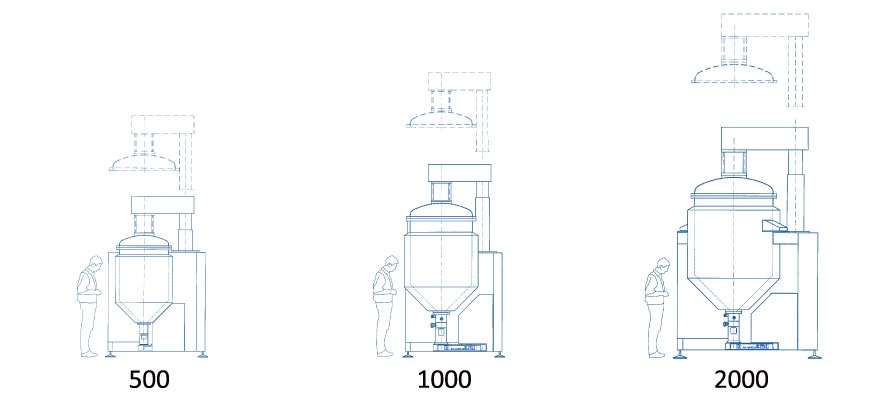

| Mixcore | MC10 | MC25 | MC50 | MC100 | MC200 | MC500 | MC1000 | MC2000 |

| Mixing vessel (L) | 13 | 32 | 65 | 130 | 260 | 650 | 1 350 | 2 600 |

| Useful volume (L) | 10 | 25 | 50 | 100 | 200 | 500 | 1 000 | 2 000 |

| Working pressure (bar) | -1 to 2.5 | -1 to 2.5 | -1 to 2.5 | -1 to 2.5 | -1 to 2.5 | -1 to 2.5 | -1 to 2.5 | -1 to 2.5 |

| Max. temperature (℃) | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Motor power (kw) | 0 37* | 1 1 | 1 5 | 2 2 | 3 | 5 5 | 7 5 | 15 |

| Output Speed 20-60r/min | 120-360 | 90-270 | 66-198 | 54-162 | 45-13 | 32.4-97.2 | 24.8-74.4 | 20.4-61.2 |

|

Max. capacity When dispersing(l/h) |

2 000 | 2 000 | 2 000 | 5 000 | 5 000 | 15 000 | 15 000 | 20 000 |

| Height (closed cover) mm | 1 065 | 1 637 | 1 817 | 2 305 | 2 421 | 3 315 | 3 749 | 4 951 |

| Height (open cover) mm | 1 151 | 2 086 | 2 417 | 2 950 | 2 421 | 3 315 | 3 749 | 4 951 |

| Width mm | 635 | 850 | 850 | 1 215 | 1 215 | 1 650 | 1 650 | 2 210 |

| Depth mm | 661 | 1 010 | 1 010 | 1 407 | 1 407 | 1 900 | 1 900 | 2 710 |

|

Model |

Design volume(L) | Max. Useful volume (L) | Min. Useful volume(L) | Dimensions (L*W*H/mm) |

| MC-H-15 | 15 | 12 | 3 |

1400*900*1600(1650) |

|

MC-H-50 |

50 | 40 | 10 | 1400*1500*1800(2100) |

| MC-H-150 | 150 | 120 | 30 |

1600*1500*2100(2250) |

|

MC-H-350 |

350 | 280 | 70 | 2000*1750*2300(2500) |

| MC-H-650 | 620 | 500 | 130 |

2300*1900*2700(2900) |

|

MC-H-1300 |

1300 | 1000 | 260 | 3000*2100*3100 |

| MC-H-2500 | 2500 | 2000 | 500 |

3100*2300*3700 |

|

MC-V-30 |

30 | 25 | 6 | 1250*1050*1700(2050) |

| MC-V-100 | 100 | 80 | 20 |

1400*1200*2200(2700) |

|

MC-V-250 |

250 | 200 | 50 | 1900*1500*2700(3400) |

| MC-V-650 | 650 | 500 | 130 |

2400*1800*3000(3900) |

|

MC-V-1300 |

1300 | 1000 | 260 | 2500*2000*3600(4800) |

| MC-V-2500 | 2500 | 2000 | 500 |

3000*2000*4000(5000) |

Customization

- A sterile version of the MIXCORE is available.

- Supporting test service

- Send us your materials sample

- Tell us your materials name/ingredients/quantity