Composition

- GS-6B Filling Machine

- SGX Screw-cap Machine

- Transportation Line

- Labeling Machine

- Auto-control System

- Labeling machine

- Inkjet coding machine

- Packaging machine

Product description

-

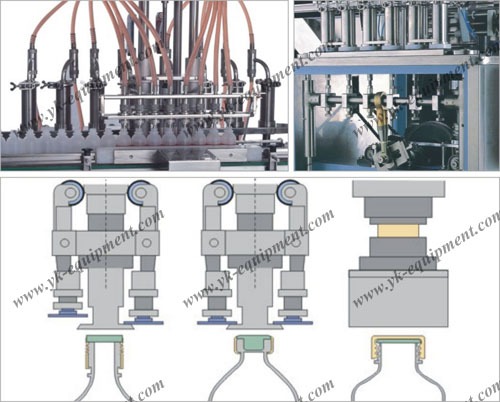

Better filling effect

- The automatic filling machine is equipped with a star shaped tray for bottle positioning, and uses a plunger pump for quantitative filling. The conveying line is equipped with corresponding sensors for automatic detection and control of bottle entry and exit. When there are no bottles or the bottle positioning is inaccurate, it automatically stops filling and alarms to ensure the cleanliness and integrity of the filling machine and finished products.

2. Smaller loss

- The automatic capping and capping machine uses a star shaped disc or conveyor to deliver bottles, which are automatically capped by the capping mechanism or taken by a mechanical arm before being sent to the capping head. The capping and capping are completed perpendicular to the bottle mouth. Suitable for sealing forms such as screw caps and pressure caps. The torque of the capping device can be adjusted to adapt to the tightness of different bottle caps and avoid damage to the caps during capping.

3. Simpler intelligent control

- using programmable control (PLC) and human-machine interface (touch screen) operation! The filling amount, yield, and speed can be directly set on the touch screen. Intelligent and reliable detection. By adopting an intelligent detection system and high-quality detection components, it can detect the presence or absence of bottles, conveyor blockages, bottle overturning, inaccurate positioning, and other errors. Ensure reliable shutdown and alarm in any stage of error.

4. Combination can be selected as needed

- It can be used alone or in combination with other existing machines, such as users configuring labeling machines, inkjet printers, packaging machines, etc. according to their needs.

Product Parameter

|

Filling Capacity |

25ml~125ml |

| Filling Speed |

60~90 bottle/min |

|

Air Pressure |

0.8Mpa |

| Gas Consumption |

>1.5m3/min |

|

Power |

1.5kw |

| Voltage |

AC380V |

|

Diameter of Bottle |

¢≥16mm |

| Applicative Bottle |

Cylinder or rectangular in shape |

|

Filling Material |

Liquid, ointment or cream |

| Volume of Pot |

100L |

|

Temperature of Filling Material |

<40℃ |

| Temperature of Wash Water |

<60℃ |

|

Transmission Speed Range |

8~20 m/min |

| Recommended Ambient Temperature |

10℃~30℃ |

|

Filling Volume |

50-1000ml |

| Filling Accuracy |

±1% |

Please send your needs to

sales@yk-machine.cn