MF-50

MF-500

MF-250

MF-1300

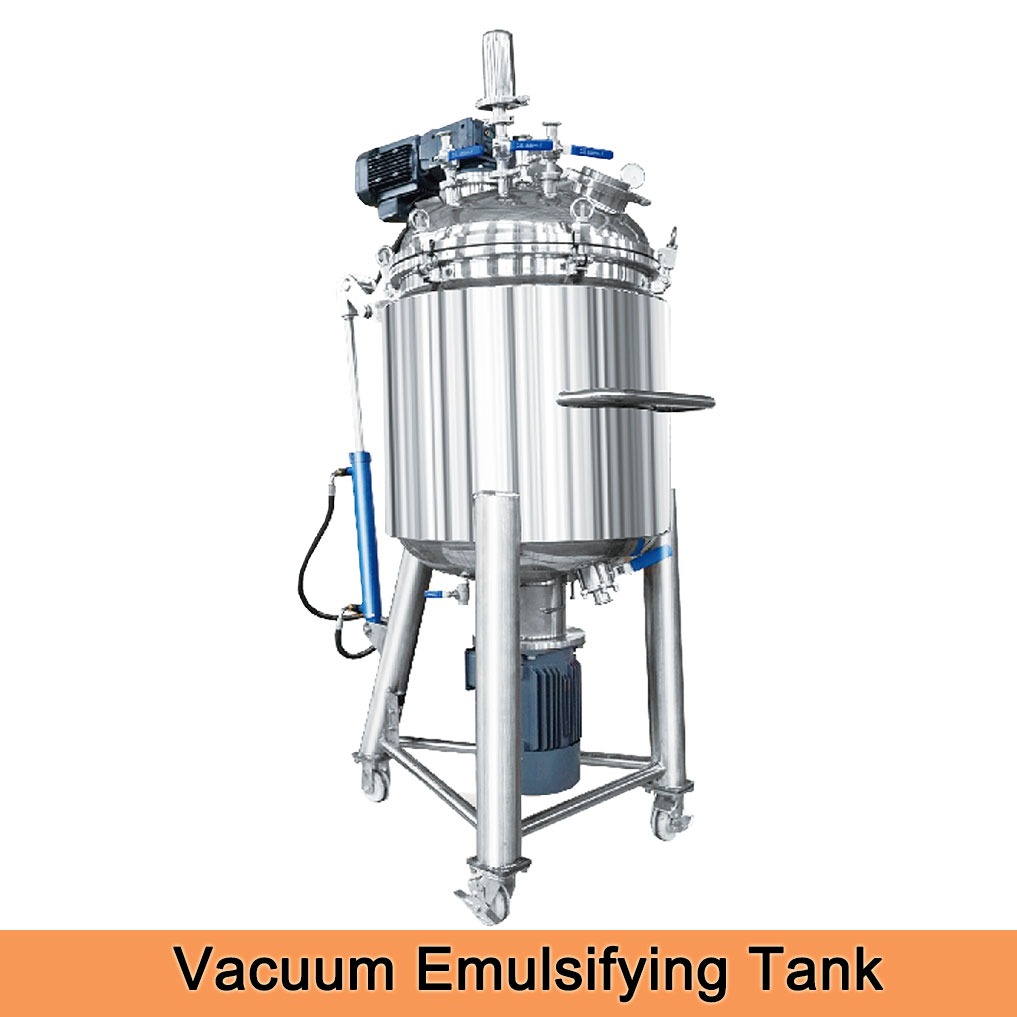

Product description of mixing tank

- The mixing tank is made of brand stainless steel.

- The welding adopts argon arc welding, and the welding seam is practical.

- The inner and outer surfaces are mirror-polished, which is easy to clean.

- YeKeey will customize special mixing tanks according to your material characteristics.

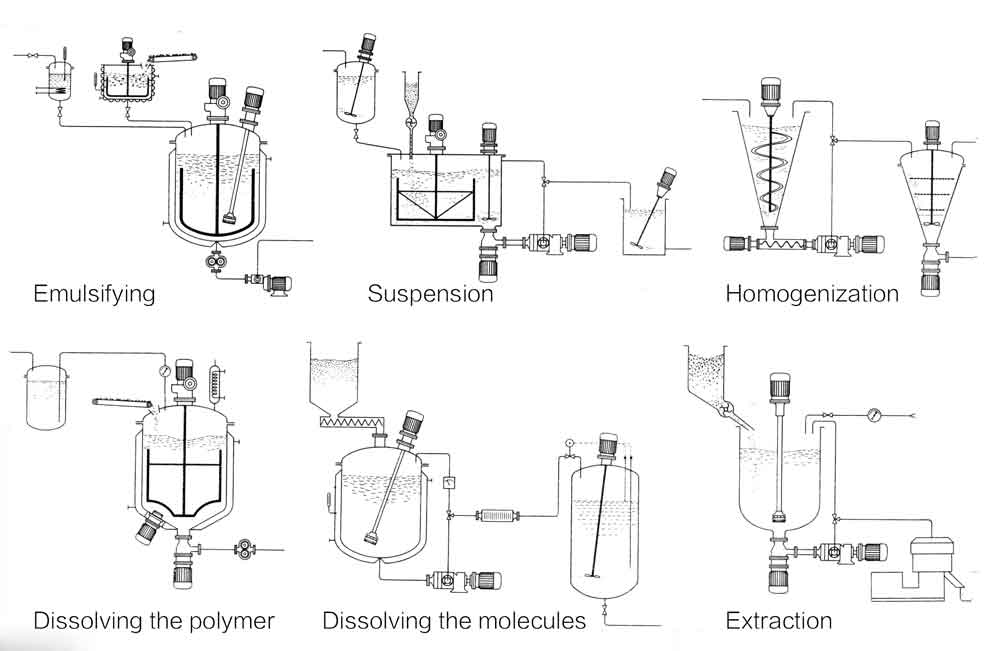

Product operation process of mixing tank

For each process, YeKeey has different equipments to match. Following is the most common process:

The Stirrers you can choose

The stirrer is choosen according to your process:

Propeller stirrer

Flow-efficient design. For drawing the material to be mixed from the top and the bottom. Minimum shearing forces. Used at medium to high speeds.

Dissolver stirrer

Radial flow, for drawing the material to be mixed from the top and the bottom. High turbulence, high shearing forces. Particle reduction.

Frame stirrer

With PEEK scraper.

Turbine stirrer

For drawing the material to be mixed from above. Generates axial flow in the vessel. Minimum danger of injury when contact is made with vessel.

Paddle stirrer

Effect is similar to that of a propeller stirrer. Medium to high speeds required.

Anchor stirrer

With PEEK scraper.

Please send your needs to

sales@yk-machine.cn