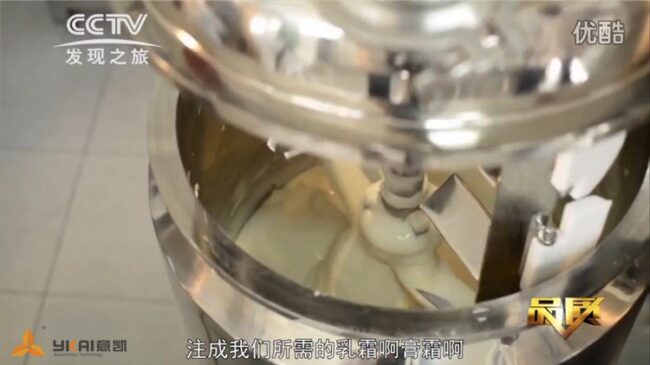

The nano vacuum emulsifier was shipped to a Thailand Pharmaceutical company

Recently, YeKeey delivered a nano 100-liter vacuum emulsifier to Thailand. The client is the pharmaceutical industry from Thailand, a modern high-tech enterprise integrating R&D, production, and sales. Its business projects cover three categories of products including health food, disinfection products, and health products. The client’s company is headquartered in Thailand, and the production base is located in…